SKF offerings

Research and Development

Global network of research and development (R&D) centres and laboratories, as well as established collaborations with major universities and research institutes, and the creation of new centres and collaborations is ongoing.

Core Competences

SKF's ability to continuously develop products and services that enhance our customers' competitive advantage is achieved in two ways: by investing in core technology areas and specialists.

Technology Clusters

SKF’s research projects are organized and run by technology clusters. SKF’s research projects are organized and run by technology clusters. SKF’s research projects are organized.

SKF can help you to :

With increasing food recalls and safety regulations becoming stricter, pro-active food safety programs have become the norm. As a result, companies must in corporate the latest advancements in hygienic design into all food processing assets while also supporting most critical goals around performance, cost and sustainability...

With increasing food recalls and safety regulations becoming stricter, pro-active food safety programs have become the norm. As a result, companies must in corporate the latest advancements in hygienic design into all food processing assets while also supporting most critical goals around performance, cost and sustainability.

Success Stories

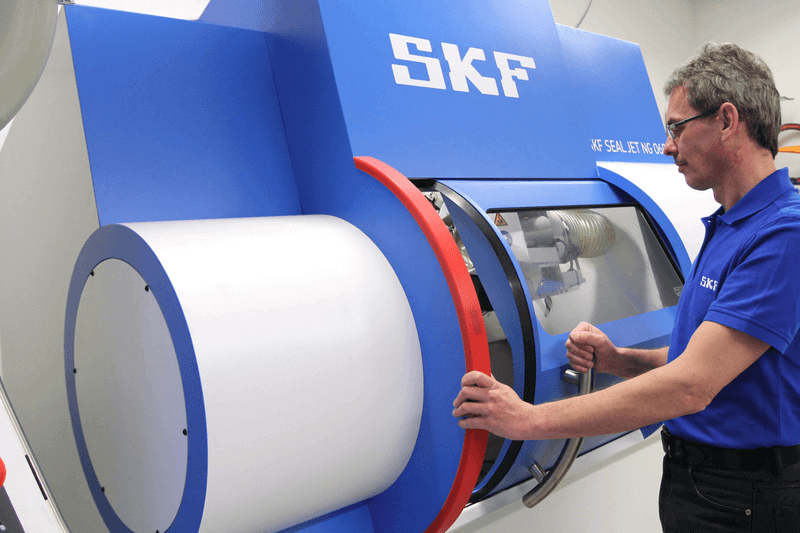

Reduces maintenance costs and increased productivity with SKF sealing solution

Following installation, the SKF solution ran for 12 months with no problems. The seals are now replaced once a year in a planned system shutdown during which all moving parts are replaced. Along with substantial annual costs savings, the beverage processing plant increased productivity by 20 million cans per year.

More

Drive-up mounting method helps paper maker achieve significant savings

Over the course of one year, the technique resulted in a significant decrease in the need for bearing replacement. The company also reduced mounting time by 75%. Together, these translated into a considerable reduction in downtime and costs.

More

An automatic, cost-effective and safe solution

SKF suggested a progressive lubrication system that would provide automatic, hands-free lubrication 24/7. SKF installed a system featuring an FB30 pump, a 30 kg tank, four outlets with progressive feeders, plus piston detectors for system reliability.

More

Customized solutions deliver all-round improvement

The customized caster roll arrangement with CARB toroidal roller bearings paired with subsequent maintenance and lubrication procedure improvements enabled the steel maker to double service life.

MoreCategory

-

Ball Bearing

-

Roller Bearing

-

Plain Bearing

-

Rolling Bearing Component

-

Ball and Roller Bearing Set